- This topic is empty.

-

AuthorPosts

-

13/11/2025 at 13:58 #87667

In today’s high-tech manufacturing environment, surface quality plays a crucial role in determining product performance, durability, and aesthetics. From aerospace components to medical devices and optical instruments, achieving ultra-smooth and defect-free surfaces is essential. This is where precision polishing becomes indispensable — a process designed to achieve microscopic smoothness, eliminate surface imperfections, and enhance both function and appearance.

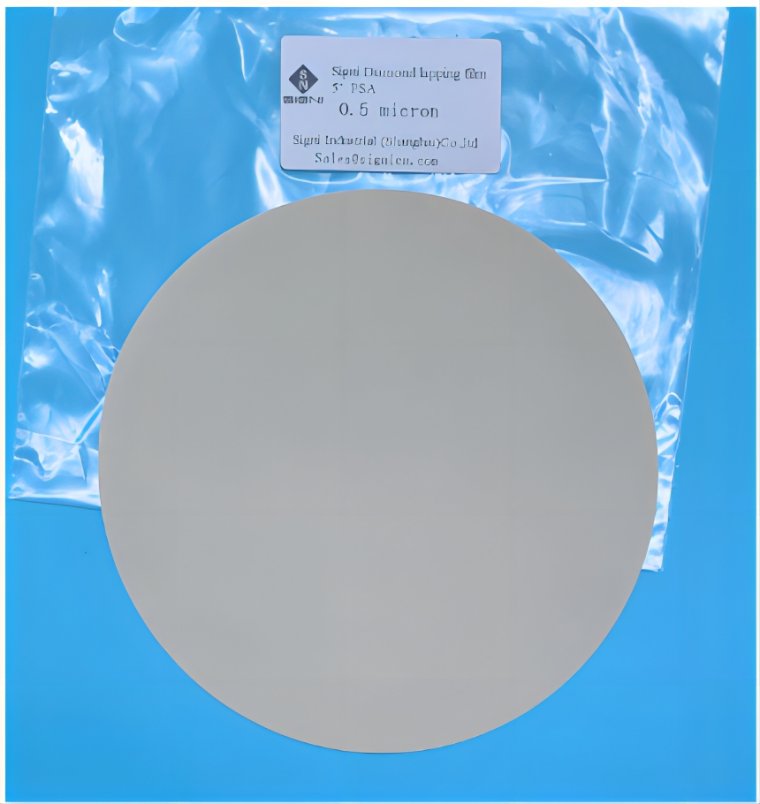

With years of experience in abrasive materials and diamond products, Signi Industrial (Shanghai) Co., Ltd. has become a trusted partner in precision finishing solutions. The company specializes in the research, development, and production of high-performance abrasives and diamond tools, offering products such as fiber-reinforced resin cutting wheels, ultra-thin grinding discs, bowl-shaped grinding wheels, and flexible abrasive wheels. With an annual production capacity of tens of thousands of tons and exports to over 40 countries, Signi Industrial provides reliable solutions that meet the demanding standards of global manufacturing industries.

In this article, we’ll explore the top benefits of precision polishing for metal and optical components — and how advanced abrasives like those from Signi Industrial make these results possible.

1. Enhances Surface Smoothness and Reflectivity

Precision polishing removes microscopic imperfections such as burrs, pits, and scratches, leaving a flawless and uniform surface. For optical components, such as lenses and mirrors, this level of smoothness is vital to achieving accurate light reflection and transmission.

For metal parts, a polished finish not only improves visual appeal but also reduces friction and wear during operation. Signi Industrial’s diamond-based polishing abrasives enable ultra-fine finishing, producing mirror-like surfaces that meet the highest industry standards.

2. Improves Performance and Functional Efficiency

In industries like aerospace, semiconductor, and precision engineering, even tiny surface irregularities can affect product efficiency. Precision polishing ensures dimensional accuracy and uniform surface texture, which translates into better mechanical performance and reliability.

By using high-quality abrasive materials — such as Signi’s resin-bonded and diamond tools — manufacturers can achieve superior control over polishing depth and consistency, optimizing both speed and accuracy in the process.

3. Increases Corrosion and Wear Resistance

A smooth, polished surface minimizes crevices and rough areas where moisture or contaminants could accumulate, thereby reducing the risk of corrosion and surface fatigue. In metal components, this not only extends service life but also enhances long-term performance under harsh conditions.

Signi Industrial’s precision abrasives are engineered to create clean, consistent finishes that strengthen protective coatings and reduce oxidation — a key benefit for parts used in marine, chemical, and energy industries.

4. Enhances Adhesion for Coatings and Plating

Before applying coatings such as paint, plating, or thin films, surface preparation is critical. Precision polishing creates an ideal surface profile that ensures better adhesion and bonding strength for subsequent treatments.

With Signi Industrial’s versatile abrasive products, manufacturers can precisely control surface texture according to coating requirements — whether for high-gloss finishes, protective layers, or functional coatings used in electronics and optics.

5. Supports Optical Clarity and Accuracy

For optical components like lenses, prisms, and mirrors, surface flatness and clarity are paramount. Any minute irregularity can scatter light or distort the optical path. Precision polishing using fine diamond abrasives allows for nanometer-level smoothness, ensuring superior optical accuracy and light transmission.

Signi Industrial’s high-precision polishing wheels and diamond products are specifically designed for such demanding applications, helping manufacturers achieve the perfect balance of clarity, consistency, and optical precision.

6. Reduces Assembly Friction and Improves Fit

In mechanical systems where multiple components interact, even small surface roughness can lead to friction, vibration, and premature wear. Polished surfaces ensure smoother assembly, tighter fits, and quieter operation, contributing to overall system efficiency.

Through precision-engineered abrasive materials and controlled polishing techniques, Signi Industrial helps industries achieve higher assembly precision and performance stability — a critical factor in automotive, robotics, and precision machinery manufacturing.

7. Demonstrates Quality and Aesthetic Excellence

Beyond performance, a polished component reflects the manufacturer’s commitment to quality craftsmanship. In sectors like consumer electronics or luxury products, surface finish directly impacts brand perception and customer satisfaction.

Signi Industrial’s wide range of abrasive tools enables manufacturers to achieve both functional and visual excellence, offering consistent polishing performance across different materials — from stainless steel to aluminum, copper, and optical glass.

Conclusion

Precision polishing is more than a finishing step — it’s a critical process that defines product quality, functionality, and longevity. Whether it’s improving light transmission in optical lenses or enhancing the durability of metal parts, the right polishing technique and materials make all the difference.

Signi Industrial (Shanghai) Co., Ltd. combines decades of expertise in abrasive material science with cutting-edge production technology to deliver solutions that meet the evolving needs of modern manufacturing. With a product portfolio covering over 1,000 varieties and exports to more than 40 countries, Signi continues to drive innovation in precision polishing and surface finishing — helping industries worldwide achieve perfection at the microscopic level.

http://www.shanghai-signi.com

Signi Industrial (Shanghai) Co., Ltd -

AuthorPosts

- You must be logged in to reply to this topic.