- This topic is empty.

-

AuthorPosts

-

15/05/2025 at 17:41 #86229

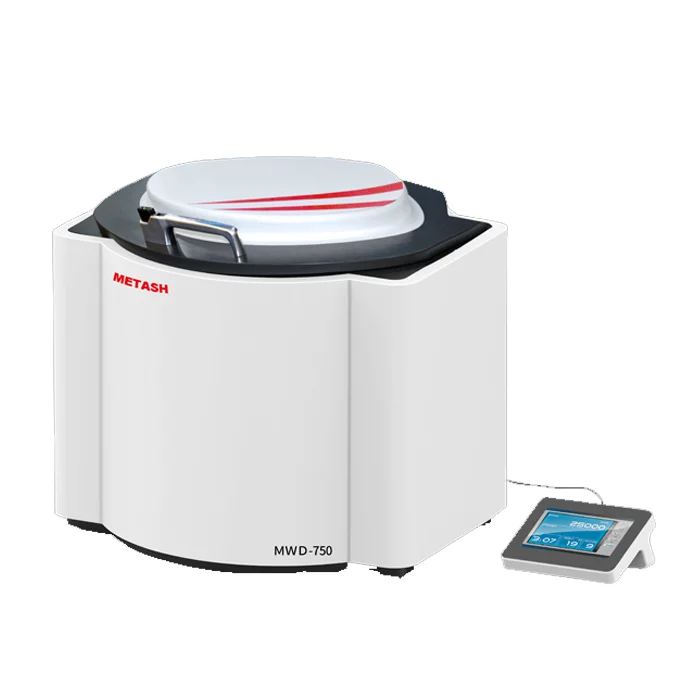

In the ever-evolving landscape of food safety and nutraceuticals, the analysis of dietary supplements has become increasingly critical. These products, often comprising complex matrices of botanical extracts, vitamins, minerals, and synthetic compounds, require highly accurate and efficient sample preparation techniques. In this blog post, Metash, a high performance laboratory analytical equipment manufacturer, will share the role of microwave digestion systems in dietary supplement analysis, workflow, etc.

Role of Microwave Digestion System for Dietary Supplement Analysis

Dietary supplements pose unique analytical challenges due to their varied composition. Unlike homogenous pharmaceutical tablets, supplements can include a vast array of ingredients, from heavy-metal-laden botanical extracts to metal-fortified powders. Trace metal analysis, especially using techniques such as Inductively Coupled Plasma Mass Spectrometry (ICP-MS) or Atomic Absorption Spectroscopy (AAS), requires that all matrix components be thoroughly digested to free analytes into a measurable form.

Conventional methods such as dry ashing and wet digestion, though still in use, are increasingly supplanted by microwave-assisted digestion due to enhanced efficiency, safety, and reproducibility. The Microwave Digestion System for Analysis of Dietary Supplement Samples offers a cleaner, faster, and more controlled alternative, significantly improving the reliability of subsequent quantification.

Fundamentals of Microwave-Assisted Acid Digestion

Microwave digestion is based on the application of microwave energy to heat chemical reagents – usually strong acids – under closed-vessel conditions. This increases the boiling point of the acids, accelerating the breakdown of organic and inorganic matrices.

A typical microwave digestion system consists of:

– Magnetron or solid-state microwave source: Delivers energy uniformly across the digestion vessels.

– Closed digestion vessels: Often made of TFM (modified PTFE), allowing high pressure and temperature digestion.

– Temperature and pressure sensors: Ensure precise control and safety during the digestion process.

For dietary supplements, a combination of nitric acid (HNO₃), hydrogen peroxide (H₂O₂), and sometimes hydrochloric acid (HCl) is commonly used to achieve full digestion of organic matrices and mineral complexes.

Microwave Digestion System Dietary Supplement Analysis Workflow

1. Sample Preparation:

The dietary supplement is homogenized and accurately weighed – typically 0.2 to 0.5 grams – into digestion vessels.

2. Reagent Addition:

A mixture of acids, usually concentrated HNO₃ and H₂O₂, is added in a clean room environment to minimize contamination.

3. Microwave Program Execution:

The vessels are sealed and subjected to a microwave digestion program. A common protocol involves ramping the temperature to 180–200°C over 15–20 minutes, holding for 10–15 minutes to ensure complete digestion.

4. Cooling and Venting:

After digestion, vessels are cooled, vented in a fume hood, and diluted to a known volume with ultrapure water.

5. Analysis:

The digested solution is analyzed using ICP-MS, ICP-OES, or AAS, depending on the elements of interest.

Advantages of Microwave Digestion System Over Traditional Techniques

1. Enhanced Digestion Efficiency:

Microwave digestion drastically reduces digestion times compared to hot plate or open-vessel techniques, often completing in under 45 minutes.

2. Superior Recovery Rates:

The closed-vessel system minimizes volatilization of analytes like arsenic, selenium, and mercury, ensuring better recovery and lower detection limits.

3. Improved Safety:

Automated pressure and temperature controls mitigate the risk of acid splashes or vessel explosions, which are more prevalent in open digestion methods.

4. Higher Throughput:

Modern systems can handle 12–40 samples simultaneously, making it ideal for high-volume laboratories.

5. Contamination Control:

The use of high-purity reagents and closed TFM vessels significantly reduces the risk of contamination, which is critical in trace analysis.

Microwave Digestion System for Dietary Supplement Analysis Applications

Heavy Metal Screening:

Regulatory bodies such as the FDA and EFSA require monitoring of toxic metals including lead (Pb), cadmium (Cd), arsenic (As), and mercury (Hg) in supplements. Microwave digestion allows consistent and complete digestion of complex herbal matrices, ensuring these elements are accurately quantified.

Nutrient Content Verification:

Microwave digestion facilitates precise measurement of essential minerals such as calcium (Ca), magnesium (Mg), iron (Fe), and zinc (Zn), which are often added to dietary supplements.

Botanical Extract Analysis:

Plant-based supplements are prone to matrix interferences. Efficient matrix breakdown via microwave digestion minimizes interferences during spectrometric analysis, enabling clear elemental profiling.

Regulatory and Methodological Considerations

In the context of Good Manufacturing Practices (GMP) and regulatory compliance, laboratories must validate digestion methods to ensure they meet the accuracy, precision, and sensitivity requirements for supplement testing.

– Validation Parameters:

– Recovery: Should be within 90–110% of certified reference materials.

– Reproducibility: Relative standard deviation (RSD) should be <5%.

– Limit of Detection (LOD): Must comply with regulatory thresholds, especially for toxic metals.

– Standards and Guidelines:

– USP <233> and <232> provide protocols for elemental impurities in pharmaceutical and dietary products.

– AOAC and ISO methods often incorporate microwave digestion in standard operating procedures.

Choosing the Right Microwave Digestion System

Selecting the appropriate digestion system depends on several factors:

– Sample Throughput: Laboratories with high workloads should opt for multi-vessel systems with rotor-based configurations.

– Temperature and Pressure Ratings: For demanding matrices like plant-based supplements, systems capable of exceeding 200°C and 30 bar pressure are recommended.

– Automation and Software: Systems with automated documentation, method libraries, and barcode integration improve traceability and compliance.

– Material Compatibility: Ensure vessels and racks are compatible with corrosive acids to extend system life and prevent contamination.

Conclusion

Microwave digestion systems have become an indispensable tool in research and regulatory laboratories due to their speed, safety, and accuracy. As supplement formulations become increasingly complex, fully utilizing microwave digestion systems for the analysis of dietary supplement samples is critical to providing reliable analytical results and maintaining the integrity of the global nutraceutical industry.

http://www.metashcorp.com

Metash -

AuthorPosts

- You must be logged in to reply to this topic.