- This topic is empty.

-

AuthorPosts

-

26/02/2025 at 18:00 #85692

With the growing demand for renewable energy, solar power has emerged as one of the most sustainable and reliable sources of electricity. To maximize the efficiency of solar panels, solar tracking systems are increasingly being used. These systems enable solar panels to follow the sun' s movement throughout the day, significantly increasing energy generation compared to fixed-tilt installations. At the heart of these tracking systems lies a crucial component—the slewing drive.

A slewing drive is a compact, self-contained system that integrates a gear mechanism and a motor to facilitate smooth and precise rotational movement. In solar tracking systems, slewing drives provide controlled movement, ensuring that the solar panels are always optimally positioned towards the sun. In this blog post, YOJU, as a high quality slew drive for solar tracker manufacturer, will share the functional advantages of slewing drive for solar tracking system.

Function Advantages of Slewing Drive for Solar Tracking System

1. High Precision for Maximum Solar Efficiency

One of the key advantages of slewing drives in solar tracking systems is their high precision. These devices are engineered to provide accurate angular positioning, allowing solar panels to follow the sun' s trajectory throughout the day. This precision ensures that solar panels remain at the optimal tilt angle, maximizing sunlight absorption and improving overall energy output.

Traditional fixed-tilt solar systems capture only a portion of the available sunlight, whereas single-axis and dual-axis tracking systems powered by slewing drives can increase efficiency by up to 35% and 45%, respectively. This increase in energy capture translates to higher electricity generation and improved return on investment for solar projects.

2. Compact and Space-Saving Design

Slewing drives are known for their compact and integrated design, which makes them an ideal choice for solar tracking systems. Unlike conventional mechanical tracking solutions that require multiple components, slewing drives combine a worm gear, an enclosed housing, and an electric or hydraulic motor into a single unit.

This design minimizes the space required for installation while ensuring strong torque transmission. Additionally, the self-locking feature of the worm gear system prevents unwanted movements caused by external forces, such as wind or mechanical vibrations, ensuring the solar panels remain securely positioned.

3. High Load Capacity and Durability

Solar tracking systems, particularly in large-scale solar farms, must withstand environmental factors such as strong winds, heavy snowfall, and temperature fluctuations. Slewing drives are built to handle high axial, radial, and tilting moment loads, making them exceptionally durable in harsh conditions.

Manufacturers use high-quality materials, precision engineering, and advanced sealing technologies to ensure that slewing drives can withstand outdoor exposure for decades without compromising performance. Many slewing drives also come with IP-rated enclosures, which protect them from dust, moisture, and corrosion. This durability reduces maintenance costs and extends the operational lifespan of the solar tracking system.

4. Self-Locking Mechanism for Enhanced Stability

One of the most critical safety features of a slewing drive is its self-locking mechanism. In solar tracking applications, maintaining the precise orientation of solar panels is crucial to preventing unnecessary movement due to wind or mechanical failures.

The worm gear design of slewing drives naturally prevents back-driving, meaning that once the drive has positioned the solar panel at the correct angle, it will remain locked in place without requiring additional energy consumption. This self-locking ability enhances system stability and prevents potential damage caused by misalignment or sudden movement.

5. Energy Efficiency and Low Power Consumption

Energy efficiency is a crucial factor in the design of any solar tracking system. Slewing drives offer low power consumption, ensuring that the tracking system does not significantly impact the overall energy output of the solar panels.

Compared to traditional gear systems, slewing drives require less torque to initiate movement, resulting in reduced energy usage. Many advanced slewing drives also integrate high-efficiency motors and smart control systems, further optimizing power consumption and enhancing overall system performance.

6. Easy Integration with Automation Systems

Modern solar tracking systems rely on automation and real-time monitoring to adjust panel angles dynamically based on the sun' s position. Slewing drives are designed for seamless integration with tracking controllers, sensors, and remote monitoring systems.

Advanced models feature encoders and position sensors, which allow for precise tracking adjustments. These smart features enable automated control, minimizing the need for manual intervention and ensuring consistent performance throughout the year. Additionally, some slewing drives support wireless connectivity and IoT-based monitoring, allowing operators to track system performance remotely.

7. Cost-Effectiveness and Long-Term Savings

Although the initial investment in a solar tracking system with a slewing drive may be slightly higher than a fixed-tilt system, the long-term benefits far outweigh the costs. The enhanced energy generation, reduced maintenance requirements, and extended lifespan of slewing drives contribute to substantial financial savings over time.

Additionally, governments and energy agencies in many countries provide incentives and subsidies for solar projects that incorporate tracking technology, making the adoption of slewing drives even more cost-effective.

8. Versatility in Various Solar Applications

Slewing drives are highly versatile and can be used in different types of solar tracking systems, including:

– Single-axis solar trackers – Ideal for utility-scale solar farms, where panels rotate along one axis (either horizontal or vertical).

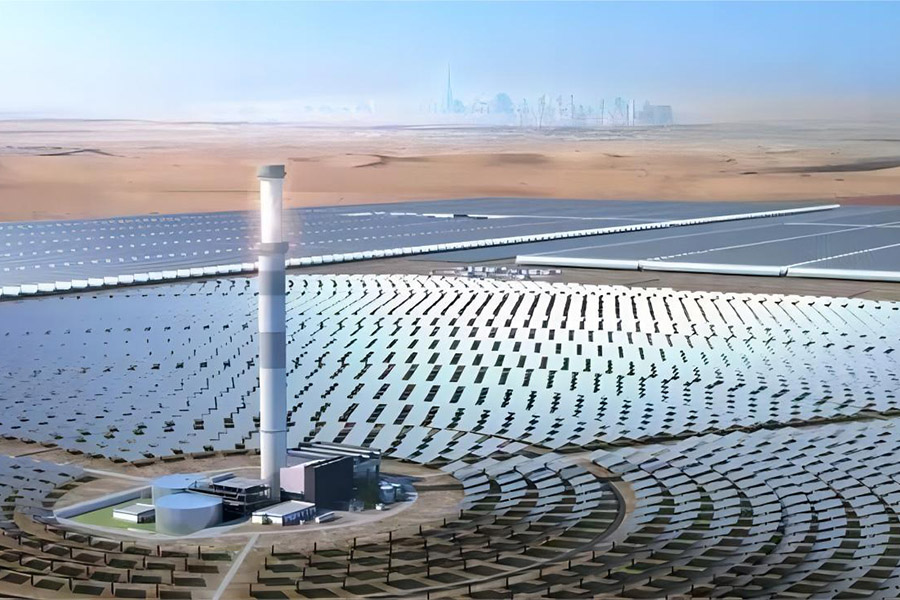

– Dual-axis solar trackers – Used in concentrated solar power (CSP) and high-efficiency photovoltaic (PV) applications, allowing solar panels to track both the azimuth and elevation of the sun.

– Parabolic trough systems – Commonly used in CSP plants, where slewing drives enable precise movement of the reflective mirrors.

Their adaptability makes slewing drives suitable for both large-scale commercial projects and small-scale residential solar tracking systems.

Conclusion

With their high precision, durability, self-locking capabilities, energy efficiency, and ease of integration, slewing drives significantly enhance the performance and reliability of solar tracking systems. Whether for large-scale solar farms or residential solar setups, slewing drives offer a reliable and efficient solution to maximize solar power generation.

-

AuthorPosts

- You must be logged in to reply to this topic.