- This topic is empty.

-

AuthorPosts

-

27/02/2025 at 18:41 #85710

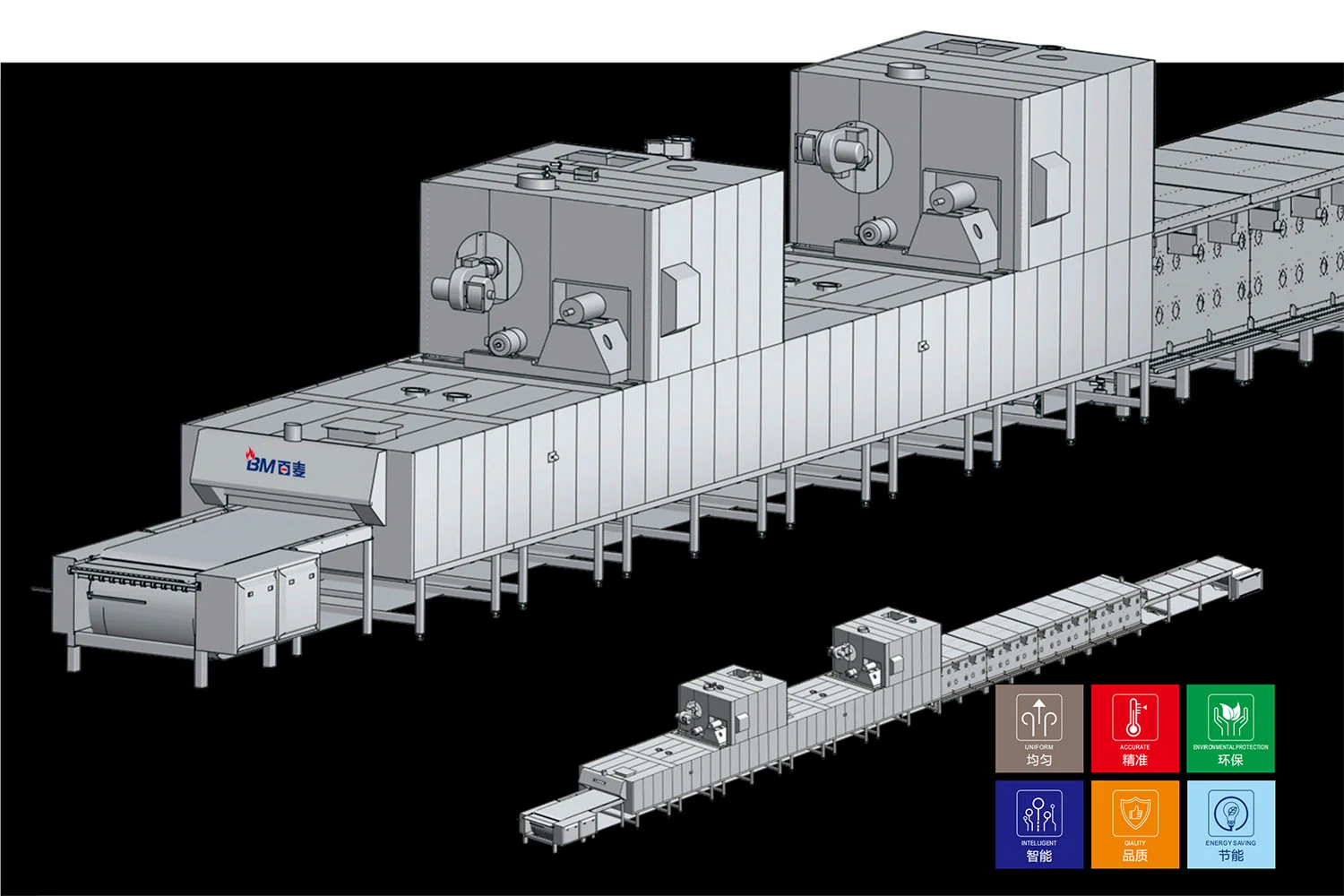

In the baking industry, technology plays a key role in improving efficiency, consistency and quality. Radiant heat tunnel ovens are designed to enhance the baking process by utilizing radiant heat, thereby providing uniform baking, energy savings and better control over the texture and taste of the final product. In this article, Baimai will share the application of heat radiation tunnel oven in baking, its advantages and its impact on modern baking operations.

Understanding Heat Radiation Tunnel Ovens for sale

A heat radiation tunnel oven is a specialized baking oven that uses radiant heat transfer to cook baked goods. Unlike conventional ovens that primarily rely on convection (hot air circulation) or conduction (direct contact with heated surfaces), tunnel ovens distribute heat using infrared radiation. The tunnel oven consists of a long conveyor belt that moves the baked products through different temperature zones, ensuring precise and controlled heating.

Radiant heat is emitted from heating elements placed strategically within the oven. The heat penetrates the product directly, allowing for even baking without excessive moisture loss. These ovens can be powered by various energy sources, including gas, electric, or infrared heaters, depending on the specific needs of the bakery.

Application of Heat Radiation Tunnel Oven in Baking

1. Large-Scale Commercial Baking

Heat radiation tunnel ovens are widely used in large-scale commercial bakeries that require high production rates. Products such as bread, buns, cookies, and pastries benefit from the continuous baking process, which significantly reduces production time. These ovens allow for automated, consistent, and high-capacity baking, making them ideal for manufacturers producing baked goods in bulk.

2. Uniform Heat Distribution for Consistent Quality

One of the biggest challenges in baking is ensuring consistent quality across batches. Traditional ovens often result in uneven baking, leading to some portions being overbaked while others remain undercooked. The heat radiation tunnel oven eliminates this issue by providing a uniform heat distribution, ensuring that all products receive the same amount of radiant heat. This results in consistent crust color, texture, and internal crumb structure, which is crucial for maintaining product standards.

3. Energy Efficiency and Cost Savings

Energy efficiency is a major concern for commercial bakeries. Traditional ovens often consume excessive energy due to heat loss and inefficient heat transfer methods. In contrast, heat radiation tunnel ovens optimize energy consumption by directly transferring heat to the baked goods. The reduced preheating time and efficient heat retention lower overall energy costs, making them an economical choice for bakeries looking to minimize operational expenses.

4. Improved Moisture Retention and Better Texture

Moisture retention is crucial in baking, as excessive drying can lead to hard or crumbly textures. Heat radiation tunnel ovens preserve optimal moisture levels by reducing excessive airflow and preventing dehydration. This leads to baked products that have a soft and fluffy crumb, crisp crust, and improved shelf life.

5. Versatility in Baking Applications

Heat radiation tunnel ovens are highly versatile and can be used for a variety of baked goods, including:

– Bread and rolls: Achieves a uniform crust and soft interior.

– Cookies and biscuits: Ensures even browning and crunchiness.

– Cakes and pastries: Maintains delicate textures without excessive drying.

– Pizza and flatbreads: Provides even baking and desirable crispiness.

This adaptability makes tunnel ovens an excellent choice for bakeries that produce a wide range of products.

6. Reduced Labor and Automation Benefits

The integration of automation in tunnel ovens reduces the need for manual labor. Traditional ovens require frequent monitoring and manual handling of baking trays, whereas tunnel ovens streamline the process by using conveyor belts and programmable temperature controls. This results in a more efficient production line, allowing bakeries to increase output with fewer workers and maintain product consistency with minimal supervision.

7. Customizable Baking Parameters

Another significant advantage of heat radiation tunnel ovens is the ability to customize baking parameters. Different products require varying levels of heat intensity, baking times, and temperature zones. Tunnel ovens are equipped with adjustable settings that allow bakers to fine-tune the baking process according to the specific needs of each product. This ensures the perfect balance between browning, texture, and flavor.

8. Hygiene and Safety in Baking

Maintaining hygiene and safety is crucial in food production. Tunnel ovens are designed with stainless steel interiors and automated cleaning systems, reducing contamination risks. Additionally, since the baking process is automated, there is minimal human contact with the baked goods, ensuring higher food safety standards.

The application of heat radiation tunnel ovens in baking has transformed the industry by enhancing efficiency, quality, and consistency. These ovens provide superior heat distribution, energy efficiency, and automation benefits, making them an essential tool for modern bakeries. While the initial investment may be high, the long-term benefits far outweigh the costs, making them a valuable addition to large-scale baking operations.

http://www.bmbaking.com

Baimai -

AuthorPosts

- You must be logged in to reply to this topic.