- This topic is empty.

-

AuthorPosts

-

16/09/2025 at 15:50 #87313

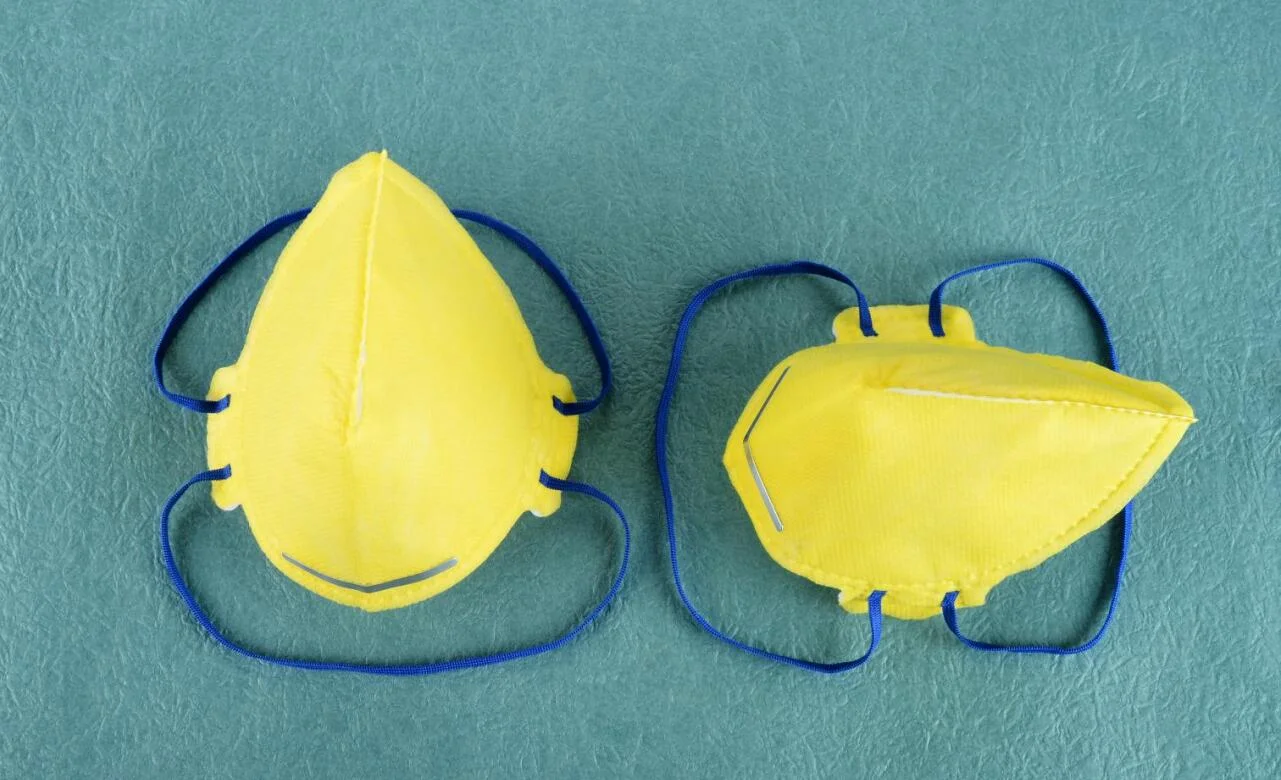

The manufacturing of dust masks requires precision, consistency, and reliable automation to ensure each mask meets the required performance and comfort standards. Among the critical machines in this production chain is the dust mask head-loop sealing machine, a specialized piece of equipment designed to attach head-loops securely to the mask body. This process ensures that the mask fits snugly and comfortably on the wearer’s face without compromising its protective qualities.

This article provides an in-depth exploration of how such machines operate, their key components, the principles behind their design, their role in mask production, and the advantages they bring to manufacturers. Broadfair Automation Equipment Co., Ltd., a high-tech enterprise engaged in research, development, production, and sales of automation equipment, has established itself as a leader in delivering high-performance head-loop sealing machines that meet stringent industrial standards.

Overview of the head-loop sealing process

Head-loops are essential components of dust masks, as they ensure proper positioning and secure attachment during use. Sealing these loops requires precision so that the mask maintains its shape, sealing efficiency, and wearer comfort. A dust mask head-loop sealing machine automates this process by combining mechanical motion, heat or ultrasonic energy, and pressure to bond the elastic or fabric loops to the mask body.

The goal is to achieve a strong, uniform, and durable bond without damaging the mask material or altering its filtration performance. This is where specialized machinery becomes indispensable, as manual attachment would be inconsistent, labor-intensive, and prone to errors.

Core principles behind the machine operation

A dust mask head-loop sealing machine works by applying a combination of controlled energy and pressure to attach the elastic bands or straps to the mask. The exact method can vary depending on the design, but the fundamental principle is to create a bond between the loop material and the mask without the need for stitching.

thermal or ultrasonic sealing principle

Many machines use ultrasonic welding technology, which generates high-frequency vibrations that cause localized heating and fusion of materials. Others use thermal bonding, where heated elements melt and fuse the materials at the interface.

controlled motion and positioning

Precise positioning mechanisms ensure that each loop is placed accurately on both sides of the mask. This is often achieved with servo-driven actuators, pneumatic grippers, or robotic arms.

pressure application and dwell time

The sealing interface is pressed under a specific force for a controlled duration. This allows the materials to bond firmly and cool or set before release.

Broadfair Automation Equipment Co., Ltd. designs its machines to maintain stable and repeatable parameters across high-volume production, ensuring that every mask receives consistent head-loop attachment.

Components that make up a head-loop sealing machine

The efficiency and performance of a head-loop sealing machine rely on a series of integrated components working harmoniously.

material feeding system

Elastic or fabric loops are fed from spools or pre-cut strips into the machine. A feeding mechanism ensures smooth delivery without tangling or stretching the material.

mask positioning platform

The mask body is positioned accurately beneath the sealing heads. Some machines feature conveyor belts or rotary indexing tables to move masks into place automatically.

sealing module

This is the heart of the machine, where ultrasonic or thermal energy is applied. It comprises:

Ultrasonic transducer, booster, and horn (for ultrasonic systems)

Heating elements and sealing dies (for thermal systems)

Pressure application units, often pneumatically or servo-actuated

control system

An intelligent control panel allows operators to adjust sealing parameters such as pressure, energy level, time, and temperature. Advanced machines incorporate programmable logic controllers (PLCs) with touch-screen interfaces for intuitive operation.

safety and quality monitoring mechanisms

To maintain quality and operator safety, machines include sensors for position detection, load monitoring, and emergency stop functions. Cameras or sensors may inspect the seal to ensure proper attachment.

Broadfair Automation Equipment Co., Ltd. integrates robust safety and control systems into their machines, minimizing downtime and ensuring compliance with industrial safety standards.

Workflow of the sealing operation

Although specific workflows vary by machine design, most dust mask head-loop sealing machines follow a structured process.

Mask loading: Masks are placed on the platform manually or via an automated feeder.

Loop placement: Elastic loops are positioned at designated attachment points.

Sealing activation: Ultrasonic or thermal energy is applied under controlled pressure.

Cooling or settling: The bonded interface is allowed to cool or set briefly.

Discharge: The finished mask is moved off the platform, ready for further processing or packaging.

This process repeats at high speed, ensuring mass production while maintaining consistent bond quality.

Advantages of using automated head-loop sealing machines

Implementing a dedicated head-loop sealing machine offers numerous benefits for mask manufacturers.

consistency and precision

Manual attachment is prone to variability in placement and bond strength. Automated machines ensure each seal is positioned identically, enhancing mask uniformity.

higher productivity

Automation allows continuous operation at high speeds, significantly increasing production output compared to manual processes.

reduced labor cost and dependency

By automating a critical production step, manufacturers reduce reliance on manual labor, lowering costs and minimizing human error.

superior bond strength

Ultrasonic and thermal bonding techniques produce strong, reliable joints that withstand regular use without breaking or loosening.

improved worker safety

Automation reduces repetitive strain and potential hazards associated with manual sealing, such as burns or misalignment injuries.

Broadfair Automation Equipment Co., Ltd. emphasizes these advantages in its machine designs, enabling manufacturers to achieve higher throughput and quality assurance.

Role of Broadfair in the industry

As a high-tech enterprise integrating research, production, and sales, Broadfair Automation Equipment Co., Ltd. is known for its expertise in developing specialized manufacturing solutions. In the field of mask production, the company provides:

research-driven innovation

Broadfair invests in the development of advanced ultrasonic and thermal sealing technologies, focusing on enhancing efficiency, durability, and adaptability.

customized equipment solutions

Every production facility has unique needs. Broadfair works closely with manufacturers to tailor machines to specific mask designs, loop materials, and production line configurations.

quality assurance and testing

Before delivery, machines undergo rigorous testing to ensure consistent sealing performance. Parameters are fine-tuned for each client’s material and product standards.

comprehensive support services

From installation and training to maintenance and spare parts supply, Broadfair provides end-to-end support to ensure seamless machine operation.

Maintenance practices for reliable operation

To maintain a head-loop sealing machine in optimal condition, manufacturers must adopt sound maintenance practices.

routine inspection and cleaning

Regularly inspecting sealing heads, feeding systems, and sensors helps prevent debris buildup that can compromise sealing quality.

calibration and parameter verification

Over time, ultrasonic horns or thermal dies may experience wear. Routine calibration ensures sealing parameters remain within specified tolerances.

lubrication and mechanical upkeep

Moving components such as conveyors, actuators, and clamping arms require scheduled lubrication and mechanical checks.

operator training

Proper training in machine handling and troubleshooting reduces misuse, minimizes downtime, and extends equipment life.

Broadfair Automation Equipment Co., Ltd. supports its clients with detailed maintenance schedules and training programs to sustain high performance over the long term.

Key factors affecting sealing quality

Several factors influence the strength and appearance of the head-loop seal:

Material compatibility: Different mask fabrics and elastic types require optimized energy and pressure settings.

Sealing temperature or ultrasonic amplitude: Incorrect settings can lead to weak bonds or material damage.

Loop tension during placement: Overstretched loops may contract after sealing, affecting mask comfort.

Environmental conditions: Dust, temperature, and humidity variations may impact the sealing process.

Broadfair engineers analyze these variables for each application, providing customized recommendations for parameter optimization.

Applications of dust mask head-loop sealing machines

Such machines are primarily used in the production of protective dust masks for industrial, construction, and occupational environments. Their applications include:

Assembly of disposable masks for particulate filtration.

Production of multi-layered dust masks for workers in mining, welding, and woodworking industries.

Manufacturing of head-loop masks used in laboratories, clean rooms, and other controlled environments.

Broadfair’s machines are deployed in various production facilities worldwide, supporting industries that demand reliable respiratory protection equipment.

Importance of automation in mask production

Automation not only enhances productivity but also ensures traceability, standardization, and compliance with regulatory requirements. Machines equipped with data logging and production monitoring help manufacturers maintain batch records, quality control, and operational efficiency.

By offering integrated automation solutions, Broadfair Automation Equipment Co., Ltd. helps mask manufacturers meet these standards with ease.

Conclusion

A dust mask head-loop sealing machine plays a vital role in the mass production of high-quality masks, ensuring each product is reliable, comfortable, and fit for purpose. By using controlled ultrasonic or thermal sealing techniques, these machines provide strong, precise, and repeatable bonds that surpass the limitations of manual attachment.

-

AuthorPosts

- You must be logged in to reply to this topic.